Sponsor, Brands, Specialists and Suppliers: The Companies that supported the Chapman /Lotus Road & Racing Programme

MelMag (Magnesium Elektron): Rims, racing on the edge

Introduction

Lotus cars sold

They were bought for their:-

- Performance –road or track

- Driving pleasure

- Reputation and image

- Aesthetics

- Symbolism

- Owner identification /personality extension etc.

All the above were integrated within a total framework design.

The above list is heavily dependent on a select group of components [either bought in proprietary or in house manufacture] that delivered the desired outcomes and met strict criteria.

Many of these components often contributed significantly to the overall aesthetic, many are extremely functional and beautiful in their own right .They formed part of a complementary whole.

In this series we examine:-

- significant Individual components from all the marque types

- Briefly explain their role /contribution /evaluation

- Analysis form and function with regard to their integration, where appropriate

- Provide suppliers/specialist advertising materials where appropriate

Understanding Lotus’s use of proprietary parts provides invaluable learning opportunities not just historical but right up to the present day. These lessons are not just applicable to automotive engineers/ designers but to the wider Industrial /Product Design professions.

The Skillful and creative adoption, absorption and integration of components was a powerful factor in the Chapman design methodology and contributed significantly to both competition and commercial success. It also feed his ability to mutate parts and materials to his desired ends.

The use of components is a fundamental skill of the Industrial Designer and the direct provision of added value.

The exact interpretation of sponsorship in conjunction with Lotus is difficult to establish objectively. The appearance of a sponsor’s logo on a car is not necessarily evidence of financial support. Access to historical archive and contracts is sought wherever possible but with the passage of time and for various reasons these are not always available or accessible to the public.

This series also embraces the specialist suppliers to Lotus. We are particularly interested in those suppliers and products that have a connectivity with aviation.

In constructing the historic sponsor series, the A&R looks only at the logos worn in period and assumes the company involved had no objection to Lotus promoting their products. The A&R sees much to be gained by the wider promotion of sponsors but in the event that a specific organization disapproves for any reason that article will be removed.

Sponsorship is an instrument of mutual benefit and promotion. Subscribers might like to see A&R articles on Sponsorship and Product Placement to understand the numerical / financial reach provided by sponsorship with its ability to identify and project status through identification.

The principle continues particularly with regard to education based exhibitions [see below for details]

Each of these articles is devoted to a company/ organization that is believed to have sponsored or supplied specialist items to Lotus.

The intention of each article is to: –

- Explain the sponsors own history and outline their products and services – past-present and future

- Explain the historical connection with Lotus and the contribution made both in competition and the production cars

- To suggest how these two interlocking facets may be translated into exciting, interpretive, educational and commercial exhibitions

Subscribers might to see complementary and structured pieces to this article: –

- Primary sponsors like Gold Leaf / John Player Specials

- Product Placement

- Separate dedicated series on engines and gearbox

- Logo on Lotus

- Wheels in this series including Ballamy, Wobbly Web, Magnesium Elektron,Speedline and OZ

Wheels in the era of the Lotus 79

Incandela writes:

“The major forces carried by the wheels are those of cornering and braking and of acceleration on the driven wheels.

During cornering the side forces generated by ground effect cars are quite staggering and are trying to bend the wheels sideways.

During braking and acceleration, forces are trying to rotate the rim of the wheel.

The critical high stress area on a rim is the tyre bead seat, where bending and rotational torques are greatest.

An important dimension of a rim is offset, which is the distance between the centreline of the rim and the mounting face. Large offset is supposed to be best for minimum weight transfer but creates stress on the suspension as it acts as leverage.

However the offset is taken into account when designing a suspension geometry and cannot be altered with cast magnesium rims. Major offset can be seen on Ferrari and Lotus rear wheels.

A rims internal diameter is limited by its suspension and brake components….

Rim width an overall diameter are limited by the regulations to match a specific tyre size.

Therefore rims cannot be taken off the shelf but are designed according to the designer’s requirements.

F1 rims are so wide now that a substantial saving in weight can be made in design and choice of materials. These days, the choice of materials lies between aluminium or Magnesium in cast form…..

Die-cast magnesium alloy rims are still very much in use…..”

Elektron Alloys

“Elektron is the registered trademark of a wide range of magnesium alloys manufactured by a British company Magnesium Elektron Limited.

There are about 100 alloys in the Elektron range, containing from 0% to 9.5% of some of the following elements in varying proportions: aluminium (< 9.5%), yttrium (5.25%), neodymium (2.7%), silver (2.5%), gadolinium (1.3%), zinc (0.9%), zirconium (0.6%), manganese (0.5%) and other rare-earth metals.[1]

Varying amounts of alloying elements (up to 9.5%) added to the magnesium result in changes to mechanical properties such as increased tensile strength, creep resistance, thermal stability or corrosion resistance. Elektron is unusually light and has a specific gravity of about 1.8 compared with the 2.8 of aluminium alloy, or the 7.9 of steel.[2] Magnesium’s relatively low density makes its alloy variants suitable for use in auto racing and aerospace engineering applications.”

MelMag Company Profile /Abbreviated summary

“Magnesium Elektron Ltd (MEL or the Mag) is a British chemical company which produces magnesium and zirconium metals and compounds.

The company was founded in 1934, as the British Magnesium (Elektronmetal) Ltd. and in 1935, Magnesium Elektron Ltd was formed as a joint venture between ICI (48%), I.G. Farbenindustrie (30%) and F.A. Hughes & Co (22%).[1] It started by producing Elektron or Elektronmetall, under license, first developed in 1908 by Gustav Pistor and Wilhelm Moschel at the Bitterfeld works of Chemische Fabrik Griesheim-Elektron (CFGE or CFG), whose HQ was in Griesheim am Main, Germany.

In 1936, the company opened a factory on Lumn’s Lane at Clifton Junction, to the north west of Manchester to produce magnesium metal. During the Second World War, the company made an important contribution to the nation’s war effort producing thousands of tons of magnesium metal alloys for the aircraft industry.

During the late 1940s, the company diversified into the production of zirconium and its compounds, and was acquired by the Distillers Company in 1951. Zirconium carbonate production commenced in 1956, to meet a growing demand from the paint, paper and textile industries.

The production of hafnium metal for use in Britain’s nuclear submarines began in 1958.

In 1961, Magnesium Elektron became a wholly owned subsidiary of the British Aluminium Company. In 1996, the company was sold to the Luxfer Group.[1]”

“Magnesium Elektron has led the magnesium industry since our company was founded in Swinton, England, in 1936.

We have been involved in every aspect of magnesium metal, starting with primary production using the Pidgeon process [1], and then moving to ingot, plate, sheet, particulate, billet, extrusions and purpose-built fabricated forms. Over the years, Magnesium Elektron ceased being just another primary supplier of magnesium and began focusing on developing, manufacturing and supplying unique high-performance magnesium alloys—many of which are patented or proprietary—for a diverse range of applications that benefit from our innovative materials and ongoing research.

[1] This silicothermic process, used to produce magnesium metal from ores, was invented in the early 1940s by Dr. Lloyd Pidgeon of the Canadian National Research Council (NRC).”

History and Products

“For many years, the worldwide motorsport industry has recognized major advantages of using sand-cast, high-performance magnesium alloys originally developed for the aerospace industry and Magnesium Elektron alloys remain popular with Formula 1 racing teams. The low weight and high strength-to-weight ratio of these alloys provide racing teams with a competitive advantage. Magnesium Elektron produces a range of patented, high strength alloys, in cast / wrought form:

- Elektron 21 – often used in transmission casings

- Elektron 43 and Elektron WE54 – typically for structural engine and chassis components

- Elektron 675 – for chassis and hydraulic applications

These alloys are particularly popular due to excellent performance under high operating stresses and temperatures.

Magnesium Elektron also manufactures high quality, Direct Chill Cast billet in a range of sizes suitable for demanding wheel forging applications.

Magnesium Elektron’s newly commissioned foundry equipment has achieved a 40% improvement in grain size. Our DC billet has excellent formability characteristics which reduces rejects and lowers processing costs for operators. Magnesium Elektron’s DC cast billet is supplied in the homogenized condition with a high quality machined surface finish ready to forge. In addition to our world beating foundry process, Magnesium Elektron is one of the only successful producers of ZK60, AZ80, and WE43 & ZW3 billet. Our DC cast billet material is used in demanding industries such as: aerospace, motorsport, military and automotive. Maximum lengths are 2080mm.”

Patent

https://patents.google.com/patent/US3790219A/en

“BACKGROUND OF THE INVENTION

Wheels for high performance cars have a wide rim width usually ranging from 8 1/2 inches to 18 inches and are manufactured individually from a light-weight alloy such as a magnesium alloy. Each wheel is cast in the selected alloy and machined to meet the requirements of the user. Generally, because of the wheel design, only the rim can be machined economically and so weight reduction at low stress areas in the region of the hub is limited by the minimum castable thickness. As a consequence the wheels are not only expensive to make but are heavier than strength and rigidity requirements dictate. Further, cast alloys, are not able to withstand stresses as well as the same alloys that have been wrought, that is shaped by pressing or spinning from rolled sheet or forged from a cast billet.

SUMMARY OF INVENTION

According to the present invention a wheel comprises a pair of circular, wrought metal dishes each having a base integral with a wall portion terminating in an outwardly projecting circumferential rib, the dishes being arranged base to base with the wall portions extending away from each other and spacer means located between the bases, a hub portion and a circumferential tension plate extending between the wall portions. At least part of the hub portion may extend between the opposed faces of the dish bases.

Preferably the spacer means is a disc-like packing piece and is advantageously formed of an expanded material for example, expanded plastics such as expanded polyurethane or polystyrene or of a material having a honeycomb structure formed from plastics material or of a light weight metal such as aluminium or aluminium alloy.

Preferably, all the parts forming the wheel are adhesively bonded one to the other, suitable adhesives include epoxy resin adhesives and an adhesive known as Redux BSL 312. Any gaps between one part and another are advantageously filled with a foaming adhesive such as Redux BSL 204.”

MELMAG Wheels

Campbell writing in 1981:-

“Many GP cars today are fitted with the MELMAG wheel, invented by Gerry Watt’s of Magnesium Elektron Ltd; of Swinton, Manchester.

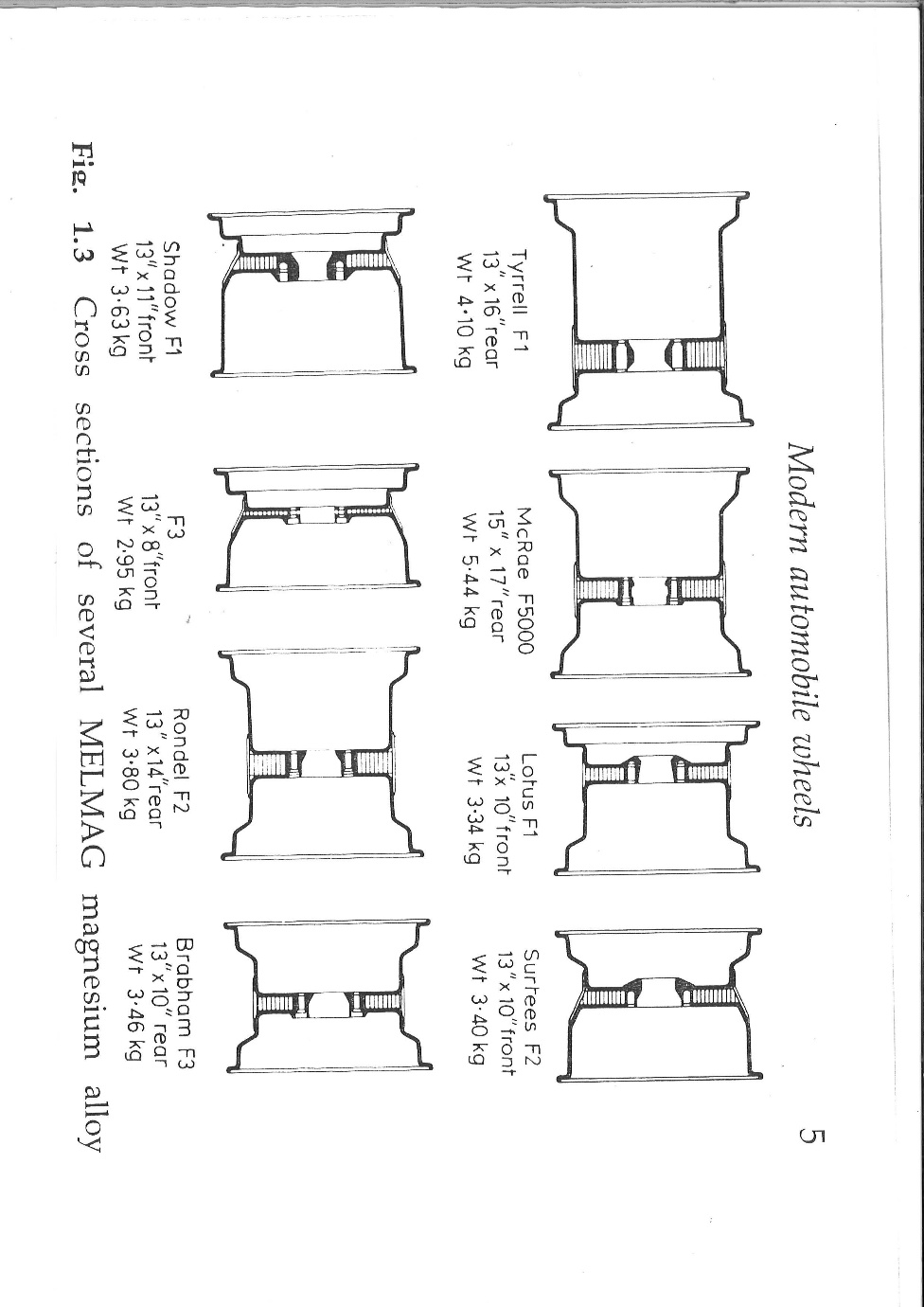

Cross section of several MELMAG designs from F3 to Formula 5000 are given in Fig.1.3.

The MELMAG wheel consists of two deep pressings in magnesium alloy ZM21.A disc of honeycomb foil mounted on the central magnesium alloy hub attachment, is used as a spacer element.a tubular tension strap envelopes the central honeycomb spacer.the complete assembly is bonded together by a high-temperature adhesive.

This sandwich construction of the wheel disk, in which a honeycomb spacer is used to separate two stressed outer skins, is an aerospace technique “

In the Chapman/Lotus era the Company was identified with:-

Figure 1: Illustration taken from Campbell

Lotus Connections

Wagstaff quotes Martin Wade:

“The MelMag disc wheel seemed to be exactly what I was looking for.This was very light, hot pressed magnesium wheel.In the event of an accident it was unlikely to facture.

The 72’s were thus equipped with these, and they became the standard for four or five races, but manufacturing problems caused too many failures …..

The possibility of being sued by the driver because of the failure of the product caused MelMag’s manufacturers to cease supply, even though I’d liked to have continued with them.

Team Lotus went back to cast magnesium wheels “

Later Wagstaff records:

‘during 1973&1974 the team also suffered three failures of the 15 inch MelMag wheels now fitted and it was decided to revert to cast 13 inch wheels.This meant that the Type 72 could no longer be fitted with tyres that used the latest Goodyear compounds.

The light and rigid Mel mag wheels were essentially two saucers with a central boss, the whole bonded together…..

Ronnie Peterson had an accident … it was found that a wheel hadn’t been glued correctly.Team Lotus successfully took Magnesium Elektron – the manufacturer of MelMag wheels to court over this . Although as Team Manage Peter Warr pointed out, this wasn’t’t done maliciously but simply to attempt to recover money spent on the programme”

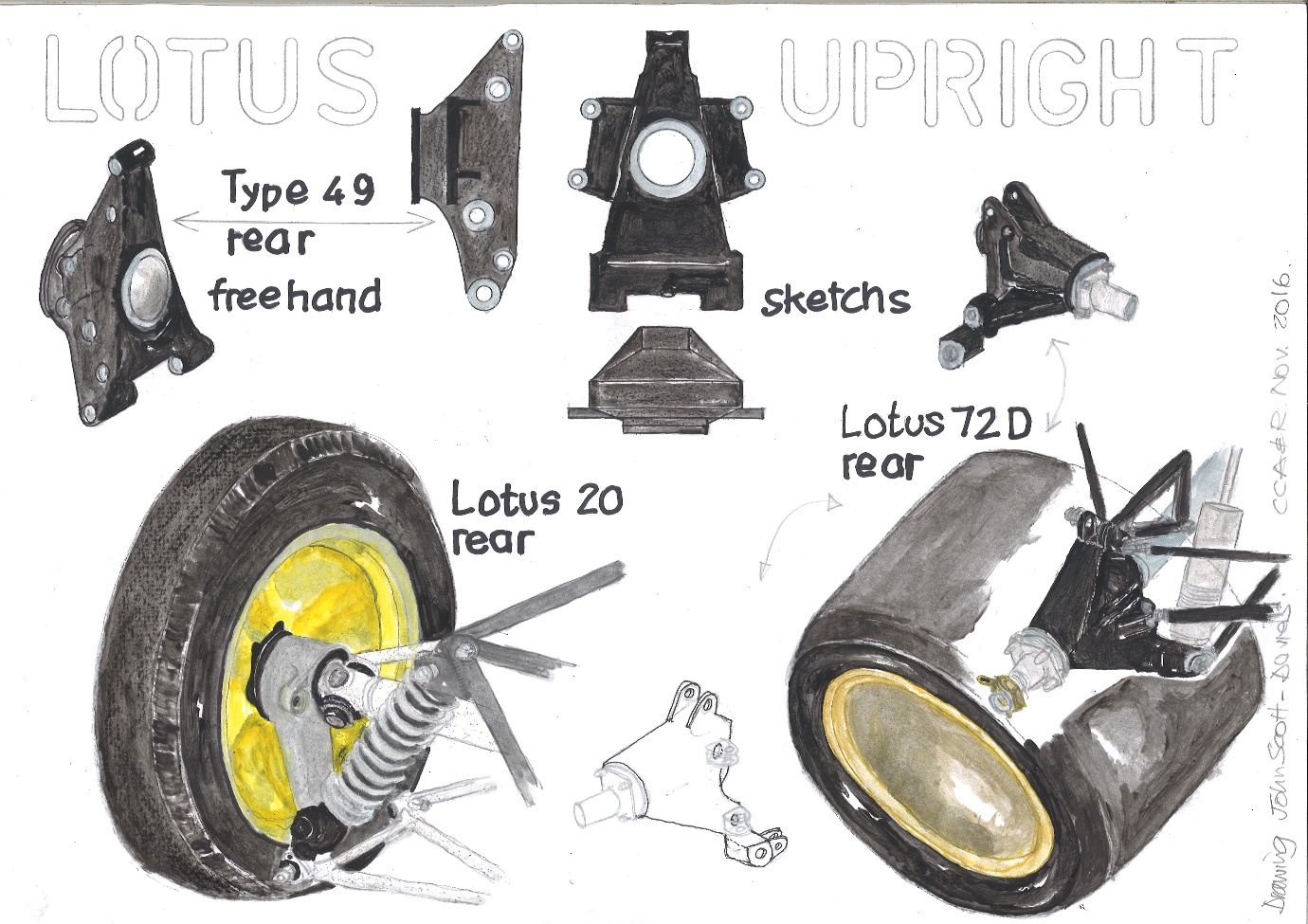

Figure 2: Editors sketch primarily of Lotus uprights but also illustrating wheels (Lotus 72 to right hand side)

Period Address for economic geography exercise

See Magnesium Elektron.

Learning Opportunities

Our learning /educational opportunities are intended to be challenging thought provoking and requiring additional research and/or analysis.

These opportunities are particularly designed for a museum/education centre location where visitors would be able to enjoy access to all the structured resources available in conjunction with any concurrent exhibition.

Understanding the potential of componentry particularly proprietary items provides some of the following learning opportunities; in this instance we suggest the following might be appropriate:-

Specific to MelMag

- What are the First Principles (Newtown) that apply to road wheels?

- How has that been translated into wheel design?

- How have tyres, suspension, aerodynamics and heat impacted on wheel design and materials?

- Study the Magnesium Elektron patent for wheels

- What testing was likely to have been carried out on these? Was it adequate with reference to Lotus failures, or were there other explanations?

- Using template benchmark Lotus 72 i.e. cross section diagram above of marques contesting F1

- List controversy that has surrounded wheel design/construction to the present day

- What is the size and value of the industry

- How has it changed? And what is its future 2020 onwards?

- Discuss the relationship with a multi-national mass-production brand/manufacturer and its links, how and why did it come into existence?

General

- Use a technical dictionary where needed to define components and roles

- Was there a viable alternative to the part under consideration?

- Is what might it have been /cost?

- Examine the suppliers/specialist advertising what does it convey? And what is its iconography?

- Integrate this item with our series on the economic geography of motor sports locations and manufacturing bases

- Has the component had exposure at any motor shows?

- Does the company continue to supply classic/heritage parts?

- What changes in technology and materials have impacted on Lotus through its history?

- How does component design impact on form and function

- Does the supplier/specialist have aviation links? If so what?

- What is the importance of ergonomics and how does it influence modern automobile design?

- Does excessive safety/ and or ergonomics impact negatively on aesthetics

- What is the impact of standardization of platforms through mark ranges and indeed shared with other manufacturers? Could uniformity ultimately impact on sales even if economies of scale improved?

- Enumerate Lotus bought in components

- How has mass production and proprietary parts assisted the specialist car market?

- Produce an engineering drawing of a selected component and consider the specification of the materials and assembly process, costs and volume

- Explore an enumerate supplier/specialists components used in other Industrial Design fields

- How did the supplier/specialist extract value from their sponsorship/support?

- Explore Graces Guide for further background detail

- Study the economic geography of the British auto industry what factors determined locations?

- What have been the causes of change and circumstance that have impacted on British motor industry?

- What has been the role of F1 /motor sport valley based around Bicester?

- What is the importance of outsourcing to the motor industry?

- Study a British car specialist like Morgan, TVR, Ginetta or Lotus where do they source parts? What are the advantages?

Exhibitions, Education, Economics and Entertainment

In the museum context the editors believe that commercial considerations are both necessary and complementary with its educational objectives.

For these reasons our suggested outline Business Plan includes provision for promoting products and services which share Chapman’s ideals of mechanical efficiency and sustainability. In addition we propose merchandising that explain and interprets the social and cultural context of Chapman’s designs in period. It’s suggested there will be catalogue for on line purchasing.

In this instance we suggest the following exhibition titles might be appropriate:-

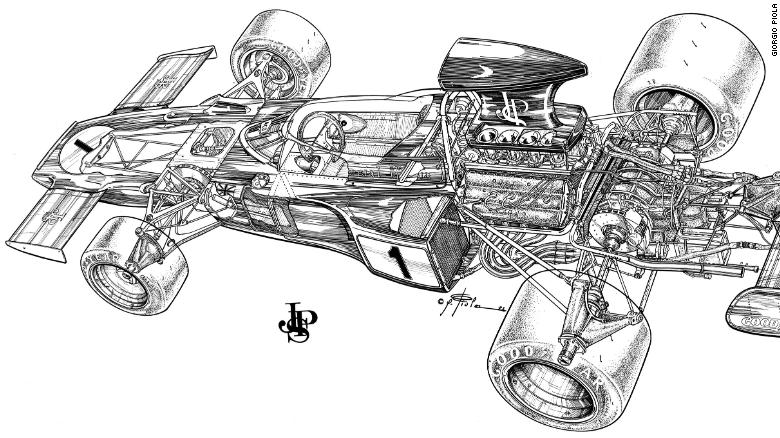

Figure 3: Giorgio Piola cutaway drawing of Lotus 72, image from the net , study wheel construction relative to tyres ,suspension etc.

Specific:-

| MelMag | Wheels | Going through hoops with Lotus |

| MelMag | Wheels | A pivotal moment |

| MelMag | Wheels | going full circle |

| MelMag | Wheels | What goes round ,comes round |

| MelMag | Wheels | Come the Revolution |

| MelMag | Wheels | Traction and trackaction |

| MelMag | Wheels | Crown wheels crowned World Champion |

| MelMag | Wheels | Spinning wheels |

| MelMag | Wheels | Rims, racing on the edge |

General:-

- Lotus Parts: Past ,Present Future

- Lotus Parts: The Winning Factor

- The Principle Part

- Act the Part

- Assign the Part

- Lotus Components

- Lotus Components :Parts and Parcel

- Lotus Sponsors, Specialist and Suppliers:Form,Function and Forte

- Lotus Components:Parts and Partiality

- Lotus Aesthetics : With little to spare

- Lotus Cars: Spare and Slender

- Product launch with title of dedicated specific relevance

Conclusion: “The whole is greater………”

There can be little doubt about the contribution made by MelMag.

They assisted Lotus perhaps indirectly to achieve multiple F1 World Championships.

What we might learn from MelMag is perhaps:

- The importance of metallurgy in industrial design

- That magnesium applications in aviation and aerospace have been transported into the motor Car and motor racing

- That Magnesium Elektron took a patent and this is a common practice and protection for a commercial idea, perhaps in this case with some limitations as applied to Lotus (but this requires a forensic level of detail to comment authoritatively )

- The MelMag wheels gave the Lotus 72 a powerful aesthetic advantage in its early John Player Specials livery

- Magnesium Elektron continues to the present applying Newton ‘s first principles into various branches of industrial design

- Metallurgical technology can have a considerable sustainable value when applied in Newton context through reduction of weight

Codling states of the Lotus 72:

“Perhaps the seminal F1 car of the early 1970’s the Lotus 72 enjoyed a remarkable archive long term of service given the rapid advances of the time. In all it would contest six seasons, long outstaying its golden period, but only because Lotus once age out thought itself trying to develop a suitable advanced replacement “

Wagstaff in his epilogue of the Lotus 72 comments:

“The Lotus 72 became one of the most instantly recognisable GP cars in history, an icon for many. It was driven by four of the greatest drivers of the era and took two of them to the World Championship….

During a five year period it won 27 percent of the GP’s for which it was entered, a figure that perhaps sums up a sometimes dominant, sometimes troubled period.

The type 72 was not quick out of the box there was a perceived fragility in its first season….

And magic there certainly is.The Lotus 72 has left us with some of the greatest images of the three litre era….”

Components were material to reliability and competitiveness.To which there were gambles and outcomes as FI demonstrates

Chapman’s design and manufacturing methodology rather confirms the adage that “the whole can be greater than the sum of the parts”.

It’s an interesting an important study to consider deployment of components. It contributes to aesthetics, assembly economics and sales [attractive components/ known accepted performance and servicing ability etc.]

It is equally and mutually relevant and beneficial to the component manufacturer.

Chapman and his colleagues often took the best / most appropriate mass produced item and almost reinvented it in its service to design objectives. In this manner many components acquired a new status and indeed their aesthetic was enhanced surrounded by the Chapman conceptual whole.

It’s also extremely significant how many of these components were also used in Lotus competition cars. This created a powerful dynamic and interrelationship. Many components:-

- Performed well in competition gaining beneficial publicity and sales

- Both the component and racing reputation carried through to road cars and assisted sales

- The component manufacturer gained disproportionate publicity and assisted products sell in other applications

- All together a beneficial spiral was commenced. Publicity of the era often opted to highlight the Lotus dimension in publicity material. In fact there was a powerful synergy.

The relationship between Lotus and is sponsor specialist suppliers is significant and worthy of close study and has lessons for Engineering, Industrial Design and Manufacturing disciplines.

Along the way it’s possible too to study the wider British motor component industry and how it has helped foster the specialist car manufacturers.

Sponsorship is a worldwide phenomenon of immense commercial impotence. Both to host and sponsor organization.

With the Passage of time it’s likely to become more sophisticated and focused and the internet /multimedia technology will play greater role.

Sponsors have existed in motorsport before Chapman but he vigorously exploited the concept with Gold Leaf c 1967/68 and set a pattern for others to follow.

Sponsors of Lotus were likely to benefit financially and in terms of exposure to an extent greater than their investment. The benefits were, and remain essentially similar to present day:-

- Access to mass international audience consistent with mass production distribution marketing branding etc.

- Demographics of viewing audience and interest groups

- Additional subsidiary /secondary advertising through media, news, magazines etc.

- Identification with market /brand /marque leader in both F1 and road cars

- Association with success and continuity evolving, developing technology, materials etc.

- In period the identification with the charm ,charisma and ability to articulate that Chapman possessed

- All the attendant glamour , drama ,danger ,and spectacle of F1

- Ability to provide conducive hospitality to conduct business

- Cost effectiveness of audience cost ratio

- Possible further complex corporate benefits

Appendix 1: Context and operation of sponsorship from the net:-

- Learn how sponsorship motives have evolved.

- Be able to differentiate between advertising and sponsorship.

- Learn the advantages of each of the key promotion tools.

- Identify the six categories of sponsorship opportunities.

- Distinguish between self-evident and strategic linkages.

- Learn the trends in spending on sponsorships.

- Gain insight as to how ambush marketing and leveraging play roles.

- Develop a basic understanding of the three special cases of sponsorship.

- Identify the five key sponsorship objectives.

- Learn the importance of each sponsorship objective.

- Understand the concept of matching.

- Learn the potential components of a sponsorship plan.

- View a comprehensive example of a sponsorship.

Gain an awareness of controversies regarding sponsorship.

Appendix 2 F1 and related racing results

http://www.snowmoose.com/LotusCars/TeamLotus/TLHistory.html

Reference:

Marks of Excellence.P.Mollerup.Phaidon Press.1997.

ISBN: 0714838381

Graces Guides

Internet websites and local History

Aircraft of the Fighting Powers.Cooper&Thetford.Vol.1.Aircraft [Technical] Publications.1940.

An extensive bibliography is provided in A&R article on John Players Specials/Gold Leaf

Industrial Design A-Z.C&P Fiell.Taschen.

ISBN: 3822863106

Lotus Book.Taylor.Coterie.1998.

ISBN: 1902351002

Art of the Formula 1 Race Car. Mann, Codling.Motorbooks.2010

ISBN:

Lotus 24, 25, 28, 29, 33.Unique.

Lotus 49, 49B, 49C, 49F.Unique.

ISBN: 1842555185

International Corporate Identity.Olins.Laurence King.1995

ISBN: 1856690377

International Motor Racing 1978.Ed by B.Gill.Macdonald and Jane’s.1978

ISBN: 035409033X

The International Motor Show. Offical Catalogue.1966

Motor Racing Directory 1955-56 [Ed by staff of “Motor Racing”] Pearl Cooper.

Motor Racing Directory.Kettlewell.

ISBN: 0906556007

Autosport A-Z Motorsport Directory. [Annual editions] Haymarket

The Automobile.Reyat.Chand.2013.

ISBN: 8121902142

Fundamentals of Motor Vehicle Technology.Hillier & Pittuck.Hutchinson.1967.

Lotus 49.Wagstaff.Haynes.2014.

ISBN: 9780858334121

Lotus 72.Wagstaff.Haynes.2012.

ISBN.978857331274

Colin Chapman.Lawrence Breedon.2002.

ISBN.1859832784

Colin Chapman.Ludvigsen.Haynes.2010.

ISBN.9781844254132

Coventry Climax Racing Engine’s.Hammill.Veloce.2004.

ISBN.1903706831

Lotus, Coventry Climax and Cosworth Engine’s.Pitt.Unique.

The Anatomy and Development of the F1 Racing Car.Incandela.Haynes.1982.

ISBN.

The 1000 BHP GP cars.Bamsey.Haynes.1988.

ISBN.0854296174

Lotus 98T.Slater.Haynes.2016.

ISBN.97808573377771

Automobile Suspension Systems.Campbell.Chapman and Hall.1982.

ISBN.412164205