Sponsor, Brands, Specialists and Suppliers: The Companies that supported the Chapman /Lotus Road & Racing Programme

Figure 1: note logo by Abraham Games (see archive and resource pieces on Festival of Britain and Design Heroes Series)

GKN When Chapman was inspired by a shaft of light and struck by a bolt of lightening

Introduction

Lotus cars sold

They were bought for their:-

- Performance –road or track

- Driving pleasure

- Reputation and image

- Aesthetics

- Symbolism

- Owner identification /personality extension etc.

All the above were integrated within a total framework design.

The above list is heavily dependent on a select group of components [either bought in proprietary or in house manufacture] that delivered the desired outcomes and met strict criteria.

Many of these components often contributed significantly to the overall aesthetic, many are extremely functional and beautiful in their own right .They formed part of a complementary whole.

In this series we examine:-

- significant Individual components from all the marque types

- Briefly explain their role /contribution /evaluation

- Analysis form and function with regard to their integration, where appropriate

- Provide suppliers/specialist advertising materials where appropriate

Understanding Lotus’s use of proprietary parts provides invaluable learning opportunities not just historical but right up to the present day. These lessons are not just applicable to automotive engineers/ designers but to the wider Industrial /Product Design professions.

The Skillful and creative adoption, absorption and integration of components was a powerful factor in the Chapman design methodology and contributed significantly to both competition and commercial success. It also feed his ability to mutate parts and materials to his desired ends.

The use of components is a fundamental skill of the Industrial Designer and the direct provision of added value.

The exact interpretation of sponsorship in conjunction with Lotus is difficult to establish objectively. The appearance of a sponsor’s logo on a car is not necessarily evidence of financial support. Access to historical archive and contracts is sought wherever possible but with the passage of time and for various reasons these are not always available or accessible to the public.

This series also embraces the specialist suppliers to Lotus. We are particularly interested in those suppliers and products that have a connectivity with aviation.

In constructing the historic sponsor series, the A&R looks only at the logos worn in period and assumes the company involved had no objection to Lotus promoting their products. The A&R sees much to be gained by the wider promotion of sponsors but in the event that a specific organization disapproves for any reason that article will be removed.

Sponsorship is an instrument of mutual benefit and promotion. Subscribers might like to see A&R articles on Sponsorship and Product Placement to understand the numerical / financial reach provided by sponsorship with its ability to identify and project status through identification.

The principle continues particularly with regard to education based exhibitions [see below for details]

Each of these articles is devoted to a company/ organization that is believed to have sponsored or supplied specialist items to Lotus.

The intention of each article is to: –

- Explain the sponsors own history and outline their products and services – past-present and future

- Explain the historical connection with Lotus and the contribution made both in competition and the production cars

- To suggest how these two interlocking facets may be translated into exciting, interpretive, educational and commercial exhibitions

Subscribers might to see complementary and structured pieces to this article: –

- Primary sponsors like Gold Leaf / John Player Specials

- Product Placement

- Separate dedicated series on engines and gearbox

- Logo on Lotus

GKN Company Profile /Abbreviated summary from net

“GKN Automotive’s roots in the automotive industry go back to the 1930s when GKN first started to produce military vehicles, including Spitfires and tanks used in the D-Day landings.

This then evolved into automotive parts production in the 1950s with GKN making a name for itself as a supplier to Jaguar and the XK120 that won the prestigious Alpine Rally.

As the 1960s accelerated demand for personal mobility, GKN started to make constant velocity joints. CV joints revolutionised the auto industry, enabling a new generation of front-wheel drive cars – including the iconic Mini.

GKN Automotive emerged as a major force in this sector and, in the subsequent decades, successfully reproduced its production quality at new plants around the world serving an increasingly global industry. And in 1988, it became the first international supplier to establish a joint venture in China, Shanghai GKN Driveshaft.

As driveline requirements evolved, so have GKN Automotive’s capabilities. The leader in complete all-wheel drive and eDrive systems since 2002, the company has an unmatched track record for delivering complete, fully integrated AWD and eDrive systems.”

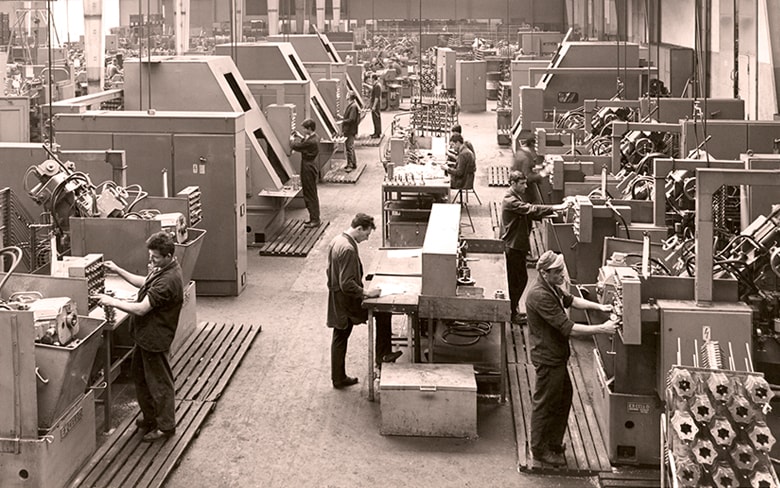

Figure 2: from Graces Guide

CV Joints etc.

“1967 GKN acquired Birfield Industries including its subsidiary Hardy Spicer and Co of Birmingham, which became GKN Birfield Transmissions, part of GKN Transmissions[1]. Hardy Spicer made constant-velocity joints which, historically, had few applications, even following the improved design proposed by Alfred H. Rzeppa in 1936. In 1959, Alec Issigonis had developed the revolutionary Mini motor car which relied on such joints for its novel front wheel drive technology. The massive expansion in the exploitation of front wheel drive in the 1970s and 1980s led to the acquisition of other similar businesses, such as Vandervell Products, leading to a 43% share of the world market by 2002.”

At one point the GKN Group was the largest international engineering group in Europe.

GKN Vandervell Ltd

This is an indirect link.

Vandervell became part of the GKN conglomerate. They manufactured engine bearings, bushes, thrust washers.

Vandervell created the Vanwall F1 car that won the World Manufacturer Championship in 1958

Chapman and Costin contributed to this car (see dedicated Archive and Resource articles)

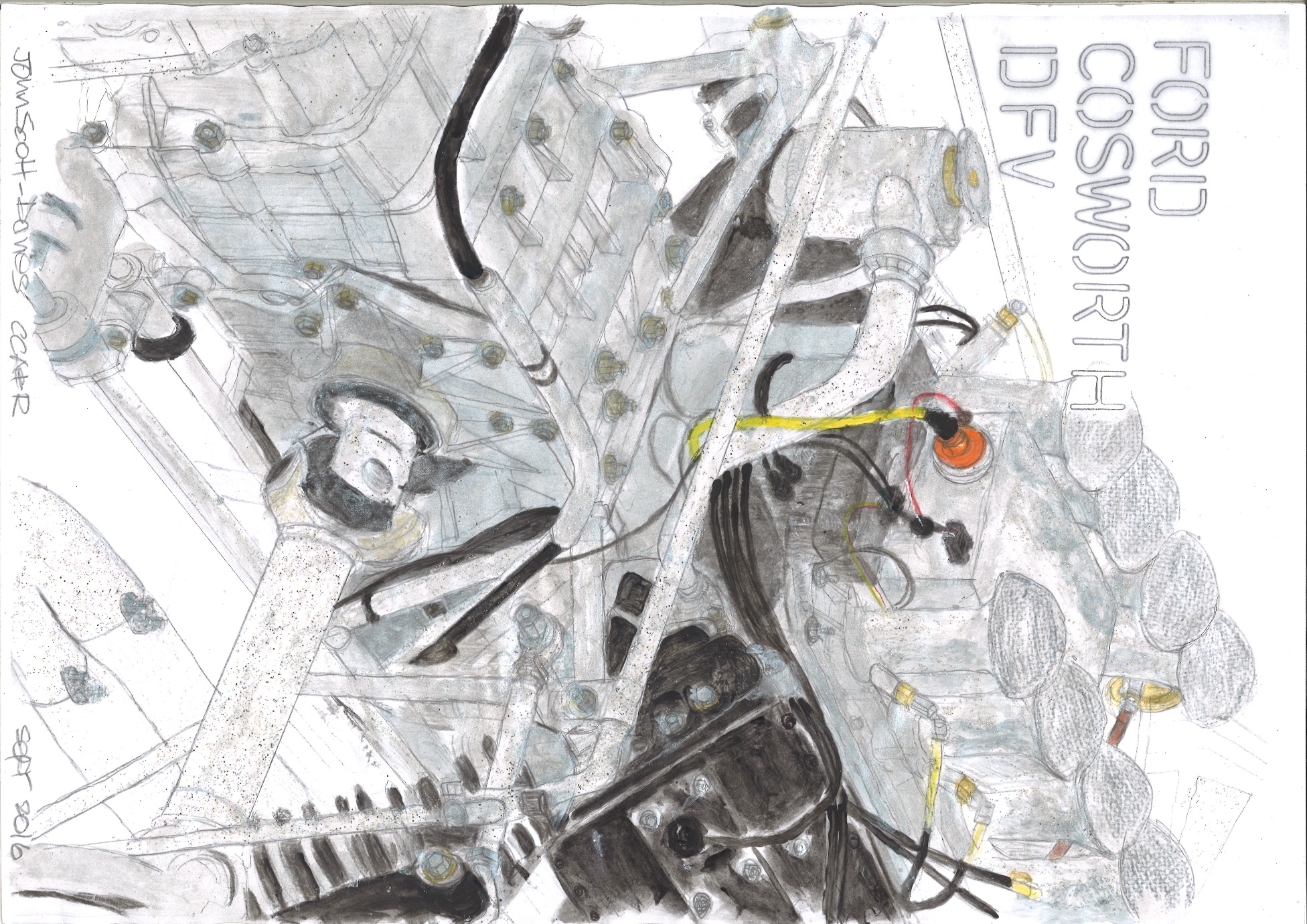

We believe they supplied the Ford Cosworth DFV and DFX.

In the Chapman/Lotus era the Company was identified with diversified products and services allied to engineering and the motor industry ranging from screws, fasteners to crankshaft and connecting rod forgings.They also had allied subsidiaries and we will cover these as appropriate.

Lotus Connections

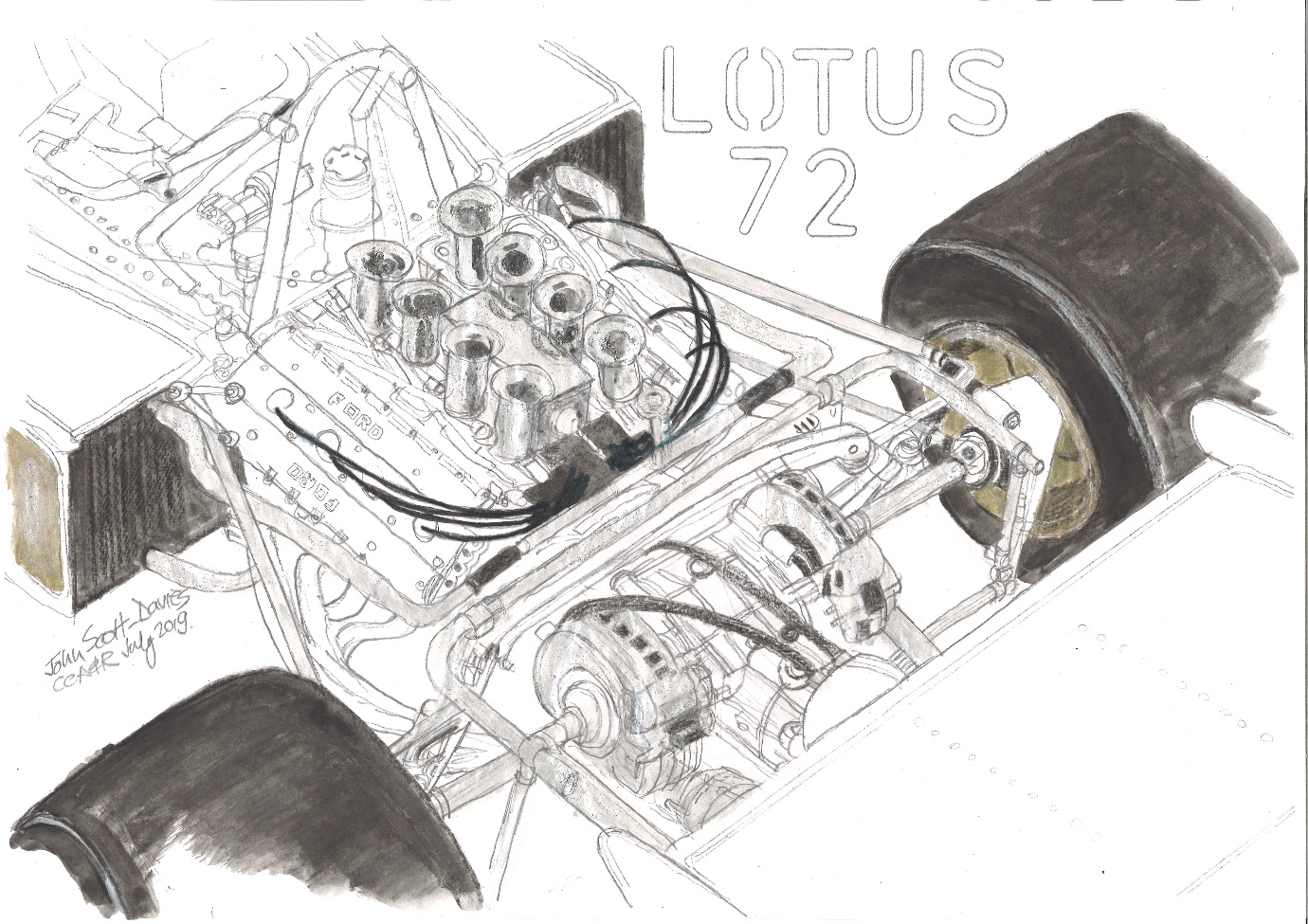

GKN is recorded as a supplier to the Lotus 72.

Wagstaff

“CV’s and drive shafts tend to come as one package on a GP car like this.The cage ,inner and outer will wear out at varying rates .These are manufactured by GKN Motorsports and have excellent repeatable quality standard”

Figure 3: editor’s sketch attempting to simplify engine, gearbox drive system

The GKN Rover Lotus Europa

This significant car was produced both for publicity and testing components.

It indicates the strong linkages with Chapman and Lotus. For this reason we direct subscribers to dedicated Archive and Resource articles.

Period Address for economic geography exercise

GKN PCL,

PO Box 55,

Ipsley House,

Ipsley Church Lane,

Redditch,

Worcestershire

B98

And

GKN Driveline/Motorsport

Unit 5 Kingsbury Business Park,

Kingsbury Road,

Minworth,

Sutton Coldfield,

West Midlands,

B76 9DL

Learning Opportunities

Our learning /educational opportunities are intended to be challenging thought provoking and requiring additional research and/or analysis.

These opportunities are particularly designed for a museum/education centre location where visitors would be able to enjoy access to all the structured resources available in conjunction with any concurrent exhibition.

Understanding the potential of componentry particularly proprietary items provides some of the following learning opportunities; in this instance we suggest the following might be appropriate:-

Specific to GKN

- Read mechanical textbooks listed and comprehend issues and distinguish between applications

- What are the forces exerted on half shafts? How does design and materials specification resist? Give examples

- Using sketch provided annotate key components

- Draw a simplified CV joint in cross section or 3D

- Outline a economic history of GKN explaining its success and survival in relation to British economic policy and international competition

- GKN had a massive presence in the Black Country one considered the Workshop of the World – how and why has this changed?

What is the size and value of the industry?

- How has it changed? And what is its future 2020 onwards?

- Discuss the relationship with a multi-national mass-production brand/manufacturer and its links, how and why did it come into existence?

General

- Use a technical dictionary where needed to define components and roles

- Was there a viable alternative to the part under consideration?

- Is what might it have been /cost?

- Examine the suppliers/specialist advertising what does it convey? And what is its iconography?

- Integrate this item with our series on the economic geography of motor sports locations and manufacturing bases

- Has the component had exposure at any motor shows?

- Does the company continue to supply classic/heritage parts?

- What changes in technology and materials have impacted on Lotus through its history?

- How does component design impact on form and function

- Does the supplier/specialist have aviation links? If so what?

- What is the importance of ergonomics and how does it influence modern automobile design?

- Does excessive safety/ and or ergonomics impact negatively on aesthetics

- What is the impact of standardization of platforms through mark ranges and indeed shared with other manufacturers? Could uniformity ultimately impact on sales even if economies of scale improved?

- Enumerate Lotus bought in components

- How has mass production and proprietary parts assisted the specialist car market?

- Produce an engineering drawing of a selected component and consider the specification of the materials and assembly process, costs and volume

- Explore an enumerate supplier/specialists components used in other Industrial Design fields

- How did the supplier/specialist extract value from their sponsorship/support?

- Explore Graces Guide for further background detail

- Study the economic geography of the British auto industry what factors determined locations?

- What have been the causes of change and circumstance that have impacted on British motor industry?

- What has been the role of F1 /motor sport valley based around Bicester?

- What is the importance of outsourcing to the motor industry?

- Study a British car specialist like Morgan, TVR, Ginetta or Lotus where do they source parts? What are the advantages?

Figure 4: editors sketch of Cosworth DFV, gearbox and drive shafts

Exhibitions, Education, Economics and Entertainment

In the museum context the editors believe that commercial considerations are both necessary and complementary with its educational objectives.

For these reasons our suggested outline Business Plan includes provision for promoting products and services which share Chapman’s ideals of mechanical efficiency and sustainability. In addition we propose merchandising that explain and interprets the social and cultural context of Chapman’s designs in period. It’s suggested there will be catalogue for on line purchasing.

In this instance we suggest the following exhibition titles might be appropriate:-

Specific:-

| GKN | Shaft drive |

| GKN | Well shafted |

| GKN | The Nuts and Bolts of F1 |

| GKN | Half shafts -divide and rule |

| GKN | Did its job – Not by Half |

| GKN | Chapman’s light bulb and light beam moment

Chapman provides a CV and job specification |

General:-

- Lotus Parts: Past ,Present Future

- Lotus Parts: The Winning Factor

- The Principle Part

- Act the Part

- Assign the Part

- Lotus Components

- Lotus Components :Parts and Parcel

- Lotus Sponsors, Specialist and Suppliers:Form,Function and Forte

- Lotus Components:Parts and Partiality

- Lotus Aesthetics : With little to spare

- Lotus Cars: Spare and Slender

- Product launch with title of dedicated specific relevance

Conclusion: “The whole is greater………”

There can be little doubt about the significant contribution made by GKN.

Wagstaff

“The Lotus 72 became one of the most recognisable GP cars in history…. It was driven by four of the greatest drivers of the era and two of them to the World Championship ….. A five year period it won 27percent of the GP’s for which it was entered…

It was a package of technologies, such as torsion bars, inboard brakes and side radiators that only someone with the imagination of Chapman could have put together in one winning car…”

They assisted Lotus achieve multiple F1 World Championships.

Components were material to reliability and competitiveness.

The commercial and economic history of GKN is worthy of detailed study.Under its umbrella organisations it supplied the British motor industry are its specialists.

GKN Motorsports comments

“We are part of the world’s number one driveline technology company and work with race teams across a number of different codes to deliver systems that help produce wins.

From the off-road endurance of the Dakar Rally to the track drama of Le Mans, high-performance GKN Automotive driveline systems have powered winners and record-setters across the line at circuits worldwide.

Our heritage in motorsport stretches back to the 1960s and we have been working with teams to optimise their vehicles since.

GKN Automotive is the leading automotive driveline technology and systems engineer. GKN Automotive is a global partner to the automotive industry. More than 50% of the 80 million new cars sold every year contain GKN Automotive technology.

GKN has a global network of 54 production facilities in 23 countries supplies over 90% of the world’s car manufacturers. Its 29,000 dedicated employees design, develop, manufacture and integrate driveline technologies that add value to vehicle programmes. GKN’s manufacturing quality, advanced engineering and system integration capabilities are continuously evolving to ensure the drivelines of tomorrow meet the mobility needs of the future.”

Chapman’s design and manufacturing methodology rather confirms the adage that “the whole can be greater than the sum of the parts”.

It’s an interesting an important study to consider deployment of components. It contributes to aesthetics, assembly economics and sales [attractive components/ known accepted performance and servicing ability etc.]

It is equally and mutually relevant and beneficial to the component manufacturer.

Chapman and his colleagues often took the best / most appropriate mass produced item and almost reinvented it in its service to design objectives. In this manner many components acquired a new status and indeed their aesthetic was enhanced surrounded by the Chapman conceptual whole.

It’s also extremely significant how many of these components were also used in Lotus competition cars. This created a powerful dynamic and interrelationship. Many components:-

- Performed well in competition gaining beneficial publicity and sales

- Both the component and racing reputation carried through to road cars and assisted sales

- The component manufacturer gained disproportionate publicity and assisted products sell in other applications

- All together a beneficial spiral was commenced. Publicity of the era often opted to highlight the Lotus dimension in publicity material. In fact there was a powerful synergy.

The relationship between Lotus and is sponsor specialist suppliers is significant and worthy of close study and has lessons for Engineering, Industrial Design and Manufacturing disciplines.

Along the way it’s possible too to study the wider British motor component industry and how it has helped foster the specialist car manufacturers.

Sponsorship is a worldwide phenomenon of immense commercial impotence. Both to host and sponsor organization.

With the Passage of time it’s likely to become more sophisticated and focused and the internet /multimedia technology will play greater role.

Sponsors have existed in motorsport before Chapman but he vigorously exploited the concept with Gold Leaf c 1967/68 and set a pattern for others to follow.

Sponsors of Lotus were likely to benefit financially and in terms of exposure to an extent greater than their investment. The benefits were, and remain essentially similar to present day:-

- Access to mass international audience consistent with mass production distribution marketing branding etc.

- Demographics of viewing audience and interest groups

- Additional subsidiary /secondary advertising through media, news, magazines etc.

- Identification with market /brand /marque leader in both F1 and road cars

- Association with success and continuity evolving, developing technology, materials etc.

- In period the identification with the charm ,charisma and ability to articulate that Chapman possessed

- All the attendant glamour , drama ,danger ,and spectacle of F1

- Ability to provide conducive hospitality to conduct business

- Cost effectiveness of audience cost ratio

- Possible further complex corporate benefits

Appendix 1 GKN history website

https://www.company-histories.com/GKN-plc-Company-History.html

Appendix 2 Specification and supplies

Lotus 72/72C/72D/72E/72F (1970-75)

| Battery | Varley |

| Bearings | Vandervell |

| Brakes | Girling |

| Brake Pads | Ferodo DS11 |

| Capacity | 2,993cc |

| Carburettors | – |

| Clutch | Borg & Beck 7.25in |

| Dampers | Koni |

| Engine | Ford Cosworth DFV |

| Fuel | Texaco |

| Fuel Capacity | 42 Gallons (190 litres) |

| Fuel System | Lucas injection |

| Fuel Tanks | FPT fuel cells |

| Gearbox | Hewland FG400 |

| Gearbox Weight | 98lb (44.5kg |

| Half-shafts | Lotus/GKN |

| Height Overall | – |

| Ignition | Lucas OPUS |

| Instruments | Smiths |

| Length Overall | 165in (4,191mm) |

| Maximum Power | 480bhp |

| Oil | Havoline |

| Pistons | Cosworth |

| Plugs | Autolite |

| Radiator | Serck |

| Rim Width Front | 10/11in |

| Rim Width Rear | 15/17in |

| Rings | Hepolite |

| RPM | 10,800 |

| Steering | Cam Gears rack and pinion |

| Suspension Front | Torsion bars and double wishbones |

| Suspension Rear | Torsion bars/lower parallel links top single link/rad. rods |

| Track Front | 58in (1,473mm) |

| Track Rear | 61in (1,549mm) |

| Turbocharger(s) | – |

| Tyres | Firestone |

| Weight (Engine) | 365lb (165.5kg) |

| Weight (Tub) | 68lb (31kg) |

| Weight (Dry) | – |

| Weight (Start) | – |

| Formula Weight | 1,213lb (550kg) |

| Wheelbase | 99in (2,514mm) |

| Wheel Diameter-f | 13in |

| Wheel Diameter-r | 13/15in |

Reference:

Marks of Excellence.P.Mollerup.Phaidon Press.1997.

ISBN: 0714838381

Graces Guides

Internet websites and local History

Aircraft of the Fighting Powers.Cooper&Thetford.Vol.1.Aircraft [Technical] Publications.1940.

An extensive bibliography is provided in A&R article on John Players Specials/Gold Leaf

Industrial Design A-Z.C&P Fiell.Taschen.

ISBN: 3822863106

Lotus Book.Taylor.Coterie.1998.

ISBN: 1902351002

Art of the Formula 1 Race Car. Mann, Codling.Motorbooks.2010

ISBN:

Lotus 24, 25, 28, 29, 33.Unique.

Lotus 49, 49B, 49C, 49F.Unique.

ISBN: 1842555185

International Corporate Identity.Olins.Laurence King.1995

ISBN: 1856690377

International Motor Racing 1978.Ed by B.Gill.Macdonald and Jane’s.1978

ISBN: 035409033X

The International Motor Show. Offical Catalogue.1966

Motor Racing Directory 1955-56 [Ed by staff of “Motor Racing”] Pearl Cooper.

Motor Racing Directory.Kettlewell.

ISBN: 0906556007

Autosport A-Z Motorsport Directory. [Annual editions] Haymarket

The Automobile.Reyat.Chand.2013.

ISBN: 8121902142

Fundamentals of Motor Vehicle Technology.Hillier & Pittuck.Hutchinson.1967.

Lotus 49.Wagstaff.Haynes.2014.

ISBN: 9780858334121

Lotus 72.Wagstaff.Haynes.2012.

ISBN.978857331274

Colin Chapman.Lawrence Breedon.2002.

ISBN.1859832784

Colin Chapman.Ludvigsen.Haynes.2010.

ISBN.9781844254132